In recent years, the development of stretch robots has marked a significant turning point in the field of robotics, redefining flexibility and performance across various industries. According to a recent report by MarketsandMarkets, the global stretch robot market is expected to grow from $1.1 billion in 2023 to $5.3 billion by 2028, reflecting a compound annual growth rate (CAGR) of 36.2%. This surge underscores the increasing adoption of stretch robots in applications ranging from manufacturing to logistics, where their unique abilities to manipulate objects of various shapes and sizes are playing a pivotal role in enhancing operational efficiency.

Prominent robotics expert Dr. Alice Johnson, a thought leader in robotic automation, emphasizes the transformative nature of stretch robots by stating, “The ability of stretch robots to adapt their grasping methods virtually in real-time is revolutionizing how we approach automation challenges.” This adaptability is not merely an advancement in technology; it represents a profound shift in operational paradigms, enabling businesses to achieve unprecedented levels of productivity and flexibility. As industries continue to evolve, stretch robots are set to become indispensable tools, driving innovations that harmonize with the dynamic demands of modern workflows.

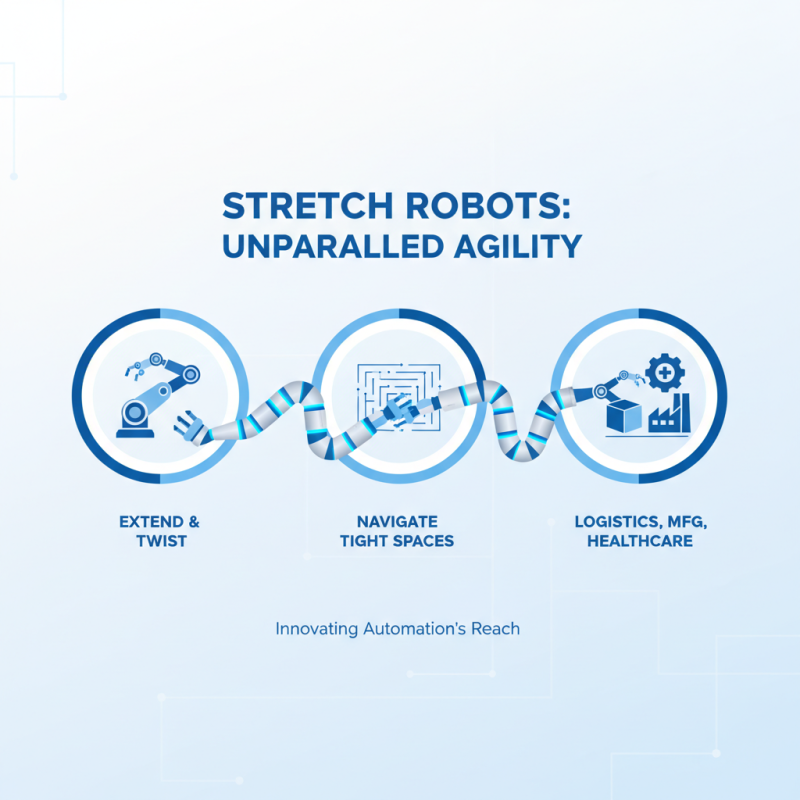

Stretch robots are a groundbreaking innovation in the field of robotics, designed to enhance flexibility and performance across various applications. These robots utilize advanced mechanisms that allow them to extend, twist, and navigate through environments with unparalleled agility. Their structural adaptability makes them suitable for tasks that require reaching into tight spaces or maneuvering around obstacles, thereby broadening the scope of automation and robotic assistance in industries such as logistics, manufacturing, and healthcare.

The importance of stretch robots in the evolving landscape of robotics cannot be overstated. As industries increasingly lean towards automation to improve efficiency and reduce operational costs, the demand for versatile robotic solutions is surging. Stretch robots not only streamline processes such as sorting, packing, and assembly but also enhance human-robot collaboration, facilitating safer and more productive work environments. Their ability to perform complex movements while maintaining precision positions them as vital tools for the future of robotics, paving the way for innovations that further integrate robots into everyday tasks.

Stretch robots are redefining the capabilities of robotic systems, particularly in the context of flexibility and performance. The advancement in soft robotics technologies has been pivotal in this transformation. According to a report by the International Federation of Robotics, the market for soft robotics is projected to grow significantly, estimating a compound annual growth rate (CAGR) of 18% through 2025. This growth is driven by innovations in materials science, particularly the development of soft actuators that allow robots to adaptively conform to various shapes and surfaces, enhancing their operational versatility.

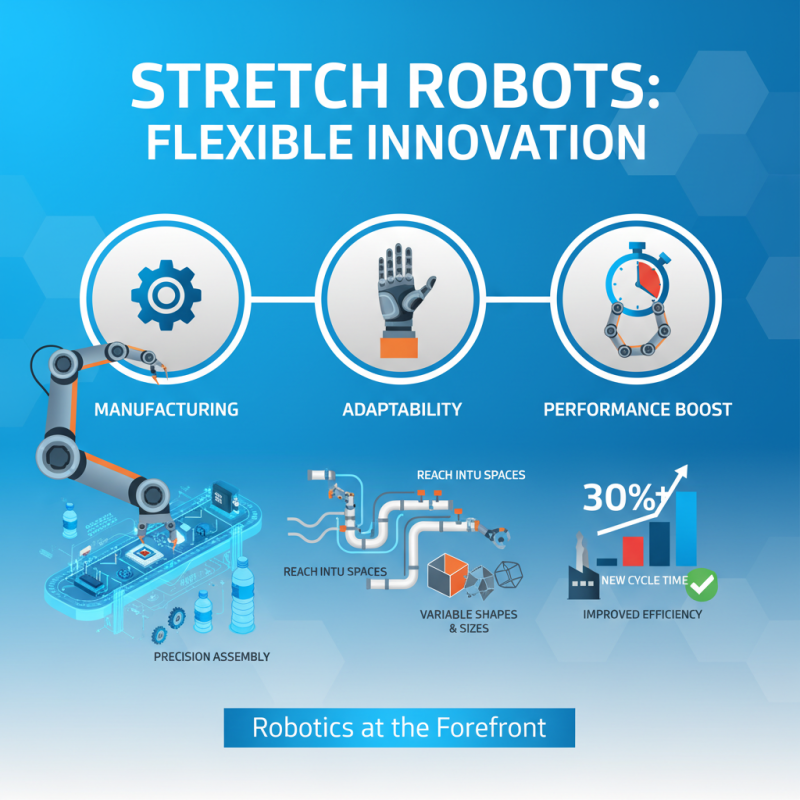

Key technologies that contribute to the flexibility and performance of stretch robots include advanced sensor integration and artificial intelligence (AI) algorithms. Sensors enable real-time feedback, allowing robots to adjust their movements and grip based on the task at hand. For instance, a study published in the Journal of Intelligent Robotics Systems highlighted that incorporating AI into robotic systems improved efficiency by 30% in complex manipulation tasks. This integration not only improves the robots' ability to handle delicate or irregular objects but also significantly reduces the time required for completion of intricate tasks. The future of robotics lies in harnessing these technologies, culminating in systems that are not only more capable but also safer and more efficient in a variety of environments.

| Robot Model | Flexibility Rating (1-10) | Payload Capacity (kg) | Maximum Reach (m) | Application Type |

|---|---|---|---|---|

| Model A | 9 | 20 | 2.5 | Manufacturing |

| Model B | 7 | 15 | 2.0 | Logistics |

| Model C | 8 | 25 | 3.0 | Healthcare |

| Model D | 6 | 10 | 1.5 | Agriculture |

| Model E | 10 | 30 | 3.5 | Research |

Stretch robots are at the forefront of innovation in various industries, showcasing unparalleled flexibility and performance. In manufacturing, these robots enhance assembly lines by adeptly reaching into intricate spaces and handling diverse components with precision. Their robotic arms, often mimicking human dexterity, can manipulate items of varying shapes and sizes, leading to improved operational efficiency and reduced time in production cycles.

In the logistics sector, stretch robots are transforming warehousing processes. They navigate tight aisles and are capable of lifting heavy objects, optimizing the storage and retrieval of goods. This adaptability not only speeds up inventory management but also ensures better space utilization within warehouses. Furthermore, in healthcare, stretch robots aid in transporting medical supplies and equipment, allowing for seamless operations in hospitals and clinics. Their ability to maneuver through crowded spaces while ensuring patient safety highlights their versatility across multiple domains.

The development of stretch robots is an exciting frontier in the field of robotics, promising unprecedented flexibility and adaptability in various applications. However, these advancements come with significant challenges and limitations that engineers and researchers must overcome. A report by the International Federation of Robotics (IFR) indicated that while the robotic market is expected to grow at a compound annual growth rate (CAGR) of 26%, the integration of stretch robots into existing production systems remains complex due to their unique structural designs and functionalities.

One of the primary challenges in stretch robot development is achieving optimal control of their movements, particularly in dynamic environments. Unlike traditional robotic arms, stretch robots must navigate a variety of terrains and handle objects of differing shapes and sizes. This necessitates more advanced algorithms and real-time processing capabilities, which can be resource-intensive. Moreover, ensuring safety during operation is critical, as the dynamic nature of stretch movements raises concerns about hazards in human-robot collaboration settings.

Tips: To enhance the performance of stretch robots, investing in robust sensory technology is crucial. Implementing advanced sensors can aid in better spatial awareness and adaptability to unpredictable variables. Additionally, developers should prioritize modular designs that allow for easy upgrades when new technologies emerge, ensuring long-term operational efficiency and effectiveness amid rapid advancements in the field.

The future of stretch robotics is poised for significant advancements, with innovations enhancing flexibility and performance across various industries. According to a recent report by ResearchAndMarkets, the global stretch robotics market is expected to grow by 23.7% annually from 2023 to 2030. This growth can be attributed to the increasing demand for automated systems in manufacturing, logistics, and beyond. As organizations seek to improve efficiency and operational capabilities, stretch robots are proving to be essential in tasks requiring adaptability and dexterity.

Innovations in materials science and artificial intelligence are fueling the transformation of stretch robotics. Lightweight and durable materials are making it possible for stretch robots to perform complex movements with precision. Simultaneously, advancements in AI allow these robots to learn from their surroundings and adapt their behaviors, further enhancing their utility. The integration of machine learning algorithms enables stretch robots to process real-time data, optimizing their functions in unpredictable environments.

Tips: When considering the implementation of stretch robotics in your operations, assess not only the current needs but also the potential for future scalability. Investing in versatile technology ensures that your operations remain agile and able to pivot as market demands evolve. Additionally, focus on training your workforce to work alongside these robots, as human-robot collaboration is key to maximizing productivity and safety in the workplace.