In recent years, the integration of commercial robots into everyday industries has been rapidly transforming the landscape of work. According to a report by the International Federation of Robotics (IFR), the global stock of operational industrial robots reached 2.7 million units in 2020, and this number is expected to grow significantly, with projections estimating an increase to over 5 million by 2025. Industries such as manufacturing, logistics, and retail are increasingly adopting commercial robots to enhance efficiency, improve safety, and reduce operational costs. A McKinsey & Company study highlights that automation through robots could potentially raise productivity by 0.8 to 1.4 percent annually, thus reshaping traditional job roles and workflows. As emerging technologies continue to advance, exploring the future of work with commercial robots becomes paramount, not only for maintaining competitive advantage but also for addressing workforce challenges in a rapidly evolving market.

The rise of commercial robots in manufacturing industries represents a paradigm shift in how products are created and delivered. As companies increasingly embrace automation, integrating advanced robotics into their workflows has become essential for maintaining competitiveness. These robots excel in precision tasks, from assembly lines to quality control, significantly reducing human error while optimizing production efficiency. This shift not only boosts output but also allows human workers to focus on more complex and creative aspects of their jobs.

Adapting to this wave of automation requires a rethinking of workforce dynamics. Businesses must invest in reskilling employees to work alongside these machines, ensuring that they can manage and maintain robotic systems effectively. Training programs that emphasize collaborative skills between humans and robots can foster a more harmonious working environment. Ultimately, the integration of commercial robots in manufacturing is not just about reducing costs—it's an opportunity to redefine roles and drive innovation across the industry. As these technologies evolve, so too will the potential for human-machine collaboration, paving the way for a more efficient and dynamic manufacturing landscape.

The integration of commercial robots in supply chain management is revolutionizing efficiency across various industries. According to a report from the McKinsey Global Institute, adopting robotic automation could enhance productivity by up to 20% within the supply chain sector. Robots are taking over repetitive tasks such as sorting, packing, and inventory management, allowing human workers to focus on more strategic responsibilities. This shift not only streamlines operations but also reduces labor costs significantly; businesses can experience a cost reduction of up to 30% in logistics when using robots.

Moreover, a study by the International Federation of Robotics indicates that industries utilizing robotics technology can expect to see substantial improvements in order fulfillment times, with some companies reporting a 50% decrease in operational delays. As robots increasingly handle tasks that require precision and speed, companies can enhance their overall service delivery. The ability to process and analyze data in real-time also leads to better decision-making and demand forecasting, thus improving customer satisfaction and retention rates. The statistical impact of robots in supply chain management is undeniable, pointing towards a future where efficiency and accuracy are paramount.

The retail and service sectors are witnessing a seismic shift with the integration of humanoid robots, marking a new era in customer experience. These robots, equipped with advanced artificial intelligence, are playing pivotal roles in enhancing operational efficiency and personalizing interactions. From assisting with stocktaking to engaging with customers through chatbots, robots are streamlining processes and ensuring a seamless shopping experience. This transformation is not only improving customer satisfaction but also creating measurable returns on investment for businesses.

Moreover, the adoption of AI-powered solutions is revolutionizing traditional workflows in retail and hospitality settings. Smart mirrors in fitting rooms can recommend suitable items based on customer preferences, while automated checkout services reduce waiting times. As businesses seek to stay competitive amidst rising labor costs, the deployment of these innovative technologies is proving essential. The shift towards automation is not just about efficiency; it's about reinventing the way customers engage with brands and making every interaction more meaningful.

| Industry | Type of Robot | Key Benefits | Adoption Rate (2023) | Customer Satisfaction (%) |

|---|---|---|---|---|

| Retail | Self-checkout Robots | Increased efficiency, Reduced wait times | 35% | 85% |

| Hospitality | Delivery Robots | Faster service, Enhanced guest experience | 50% | 90% |

| Grocery | Inventory Management Robots | Improved stock accuracy, Cost savings | 40% | 82% |

| Banking | Virtual Assistant Robots | 24/7 customer support, Reduced operational costs | 45% | 88% |

| Food Service | Order Taking Robots | Enhanced order accuracy, Faster table turnover | 30% | 86% |

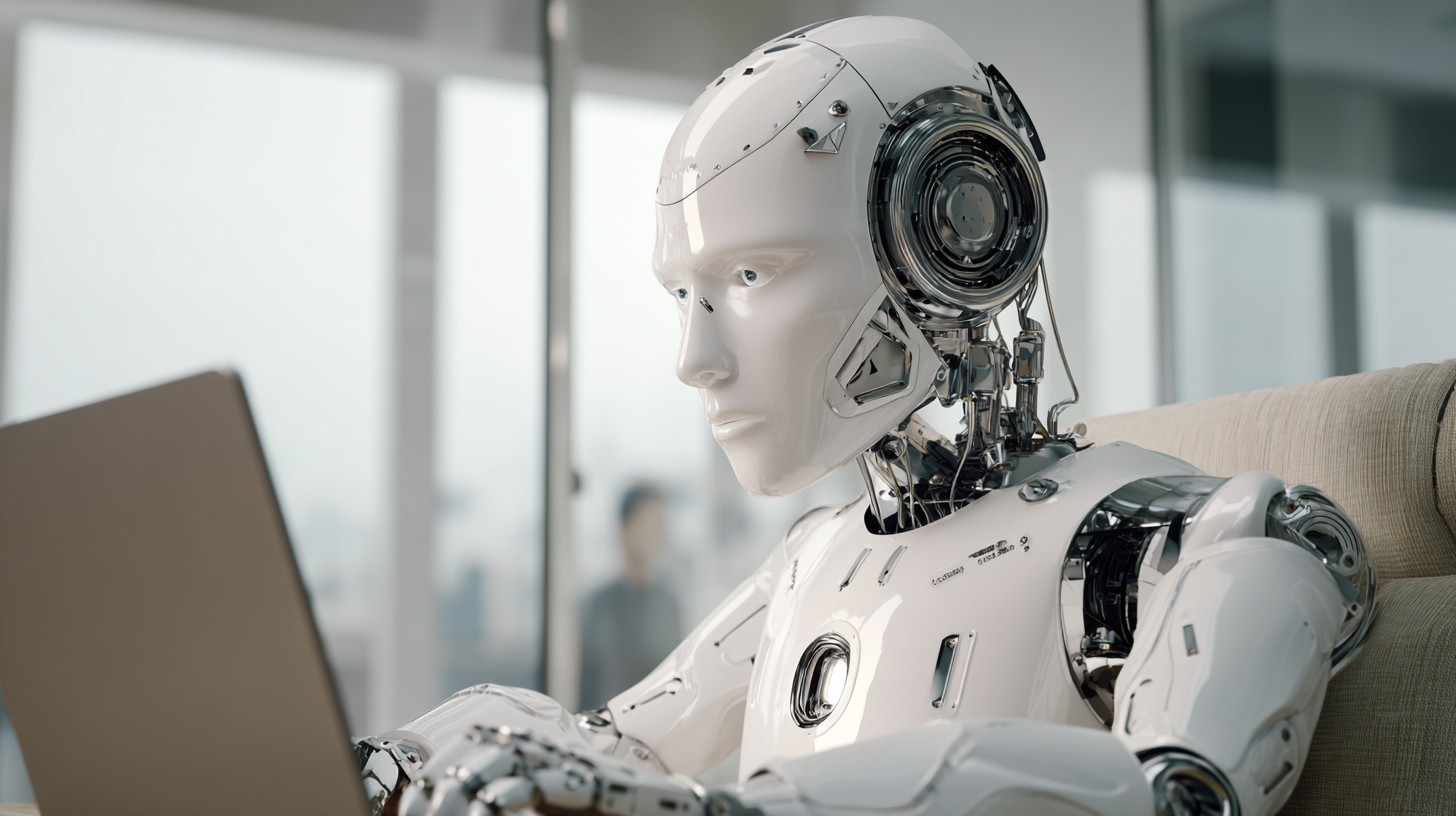

As industries increasingly adopt commercial robots, the future of work is shifting dramatically. The integration of robotic technology into everyday operations fosters the need for a workforce evolution, where human employees undergo training to effectively collaborate with machines. This collaboration not only enhances productivity but also emphasizes the importance of adaptability within the workforce. By equipping employees with the skills to work alongside robots, companies can maximize operational efficiency while reducing the risk of job displacement.

Training programs must focus on both technical skills and soft skills, bridging the gap between human workers and robotic counterparts. Employees should learn how to operate, maintain, and troubleshoot robots as well as develop critical thinking and problem-solving abilities. This dual approach ensures that the workforce remains agile and prepared for the dynamic demands of future work environments. Organizations must invest in continuous learning initiatives to facilitate this evolution, fostering a culture where human-robot collaboration thrives and drives innovation across various industries.

The implementation of commercial robots across various industries presents a compelling economic opportunity, as businesses seek to optimize their operations amid rising labor costs and productivity demands. According to a report by the International Federation of Robotics, global sales of service robots are projected to reach 40 million units by 2025, indicating a significant shift towards automation. This increase highlights the potential for cost savings, with companies reporting a reduction in labor costs by up to 30% through robotic integration in sectors like manufacturing and logistics.

Furthermore, the cost-benefit ratio of adopting these technologies can be substantial. A study from McKinsey & Company indicates that companies that invest in automation technologies can expect a return on investment (ROI) ranging from 30% to 200%, depending on the industry and implementation scale. For instance, in the agriculture sector, autonomous machinery can enhance efficiency, allowing farmers to save on labor while increasing their yield by approximately 20%. This economic analysis showcases that while initial investment may be significant, the long-term savings and productivity enhancements can make commercial robots an attractive proposition for everyday industries.

This chart illustrates the estimated cost savings and productivity improvements associated with the implementation of commercial robots across different industries. The data reflects potential financial impacts in terms of annual savings versus the initial investment cost.